Revolutionizing Nail Clipper Production: The Automatic Edge-Opening Process

When it comes to personal grooming, a nail clipper is an indispensable tool. Its effectiveness hinges on one critical factor: the sharpness of its blade edge. A dull or inconsistent blade can turn a simple trim into a frustrating experience, which is why achieving uniform sharpness in every nail clipper is a top priority for manufacturers. Historically, this has been a challenge—until now. At our factory, we’ve developed an innovative semi-automatic edge-opening process that transforms how nail clippers are made, ensuring exceptional sharpness and quality consistency across every unit produced.

The Challenge of Manual Grinding

Traditionally, sharpening the blade edges of a nail clipper was a manual task, dependent entirely on the skill and precision of individual workers. While skilled artisans could produce sharp blades, this hands-on approach had a significant drawback: inconsistency. The quality of the blade edge varied from one nail clipper to the next, making it difficult to maintain reliable standards during mass production. Uneven sharpness not only affected the user experience but also posed challenges for quality control, leading to inefficiencies and wasted resources.

Recognizing these limitations, our factory set out to find a better way. The result? A groundbreaking automatic edge-opening process that redefines nail clipper manufacturing.

A Game-Changing Innovation

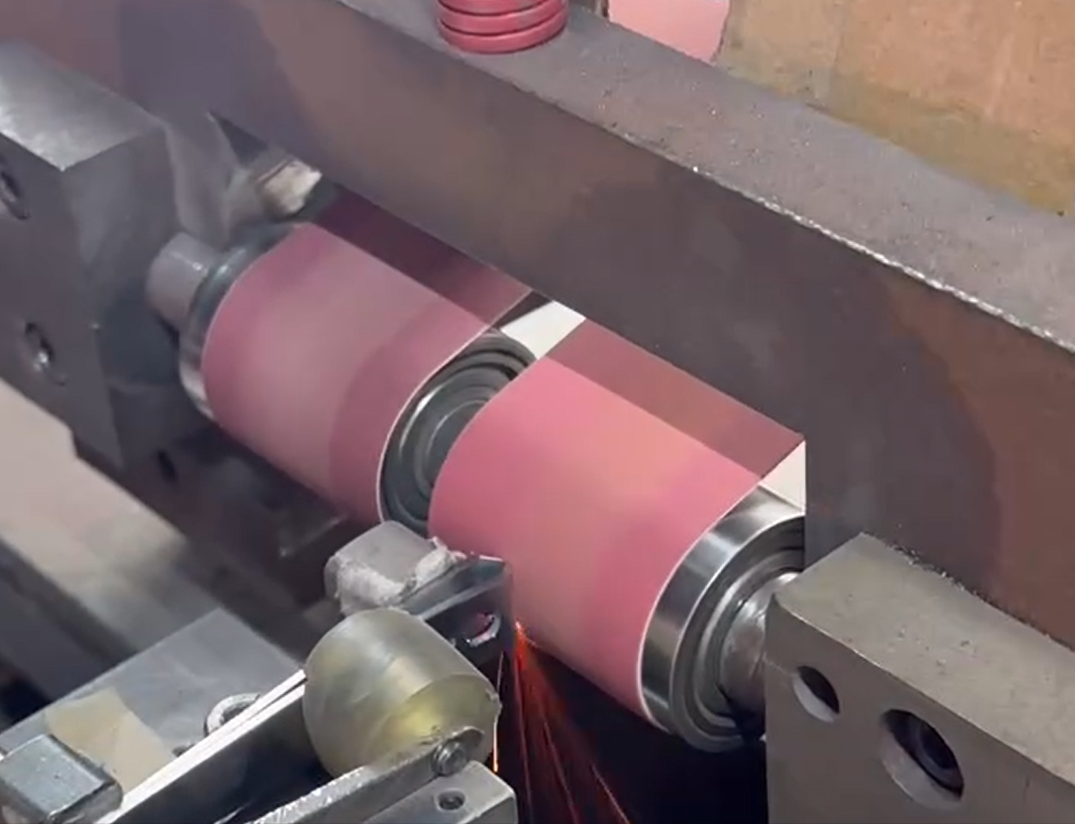

Our semi-automatic edge-opening process is a proprietary technology, developed and refined in-house by our expert engineering team. Unlike the unpredictable manual grinding method, this process uses a custom-built machine designed to sharpen nail clipper blades with unmatched precision. At the core of the system are two cylindrical rollers coated with high-quality abrasive material. These rollers work in tandem, applying controlled pressure and movement to shape and sharpen the blade edges as they pass through the machine.

The process is semi-automatic, blending advanced automation with human oversight. Operators feed pre-formed nail clipper blanks into the machine, where a guide system ensures perfect alignment. The rollers then take over, grinding the edges with consistent force and speed. This combination of technology and craftsmanship eliminates the variability of manual methods, delivering blades that are uniformly sharp and durable.

How It Works: Precision in Action

The automatic edge-opening process is as fascinating as it is effective. Here’s a closer look at how it transforms nail clipper production:

- Robust Design: The machine features a sturdy metal frame and adjustable components, built to withstand the demands of high-volume manufacturing.

- Abrasive Rollers: Two large cylindrical rollers, covered in pink abrasive material, rotate at a calibrated speed to sharpen the blade edges. Sparks and metal shavings—visible during operation—highlight the intensity of the grinding action.

- Guided Precision: A translucent or rubber guide positions each nail clipper blank accurately, ensuring the rollers sharpen the edge to exact specifications.

- Controlled Environment: With features like air or coolant hoses, the machine maintains optimal conditions, preventing overheating and preserving blade integrity.

This meticulous process guarantees that every nail clipper leaving our production line boasts a razor-sharp edge, ready to deliver a clean, effortless cut.

The Benefits: Sharpness, Consistency, and Efficiency

The shift to this semi-automatic edge-opening process brings a host of advantages that set our nail clippers apart:

- Superior Blade Sharpness: Each nail clipper offers a precise, clean cut, enhancing the user experience.

- Unmatched Consistency: The machine ensures that every blade meets the same high standard, eliminating the variability of manual grinding.

- Boosted Efficiency: By reducing reliance on labor-intensive handwork, we’ve streamlined production, cutting costs and speeding up output without compromising quality.

- Enhanced Quality Control: The precision of the system allows us to enforce stricter quality checks, ensuring only top-tier nail clippers reach our customers.

These benefits translate into a product that’s not only reliable but also a cut above the competition—literally.

Visual Proof of Innovation

Our automatic edge-opening process isn’t just a concept—it’s a reality captured in action. Close-up images of the machine reveal its intricate design: the pink abrasive rollers spinning with purpose, the sturdy frame supporting the operation, and the sparks flying as blades take shape. A gloved hand overseeing the process underscores the balance of automation and human expertise. These visuals tell the story of a factory committed to pushing boundaries in nail clipper manufacturing.

Leading the Way in Nail Clipper Manufacturing

At our factory, innovation drives everything we do. The development of the semi-automatic edge-opening process reflects our dedication to solving real challenges in nail clipper production. By replacing the unstable manual grinding method with this advanced technology, we’ve elevated the quality and reliability of our products, setting a new standard for the industry.

For customers, this means a nail clipper they can trust—sharp, consistent, and built to last. For partners, it’s a testament to our commitment to excellence and our ability to innovate from within. As we continue to refine our processes and embrace cutting-edge solutions, we’re proud to lead the charge in delivering the best nail clippers on the market.