As a prominent tweezer manufacturer, Olimor Beauty leads the industry in crafting precision grooming tools that combine functionality with elegance. Our commitment to excellence ensures that every tweezer is designed for optimal performance, utilizing advanced materials and techniques to meet the demands of modern users.

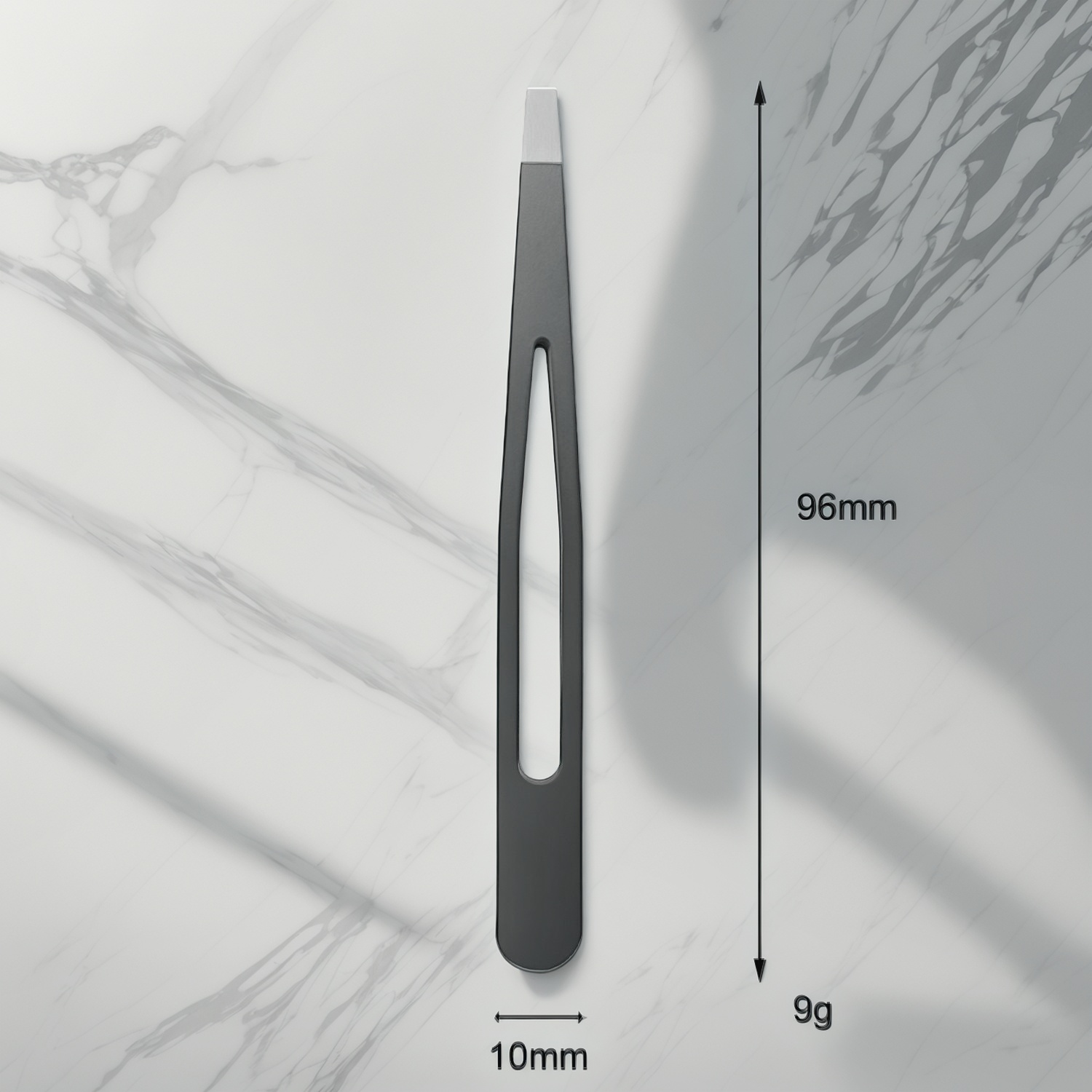

The process of tweezer manufacturing involves meticulous engineering, starting with high-grade stainless steel that is precision-machined for strength and accuracy. At Olimor Beauty, we employ ergonomic designs to enhance user control, with tools weighing just 9 grams and featuring tapered tips for minimal hair breakage. Our technical commitment includes rigorous quality control, where each step from material selection to final assembly is inspected to guarantee reliability and safety.

Tweezer suppliers are essential in sourcing premium components that uphold product integrity, while tweezer factories like ours integrate these into streamlined production lines. This collaboration allows for efficient scaling, ensuring that tweezer exporter demands are met with consistent quality. For instance, our factory processes involve automated precision cutting and polishing, reducing defects and enhancing the non-slip grip for better handling during use.

Tweezer exporters facilitate global distribution, connecting manufacturers like Olimor Beauty to international markets, while tweezer wholesalers handle bulk supplies for retailers. Additionally, tweezer OEM services enable customized production, tailoring designs to specific client needs without compromising on technical standards. This ecosystem supports innovation, such as our 96mm height and 10mm width models, which are engineered for portability and precision in everyday grooming tasks.

Technical Aspects of Tweezer Manufacturing

The process of tweezer manufacturing involves meticulous engineering, starting with high-grade stainless steel that is precision-machined for strength and accuracy. At Olimor Beauty, we employ ergonomic designs to enhance user control, with tools weighing just 9 grams and featuring tapered tips for minimal hair breakage. Our technical commitment includes rigorous quality control, where each step from material selection to final assembly is inspected to guarantee reliability and safety.

The Role of Tweezer Suppliers and Factories

Tweezer suppliers are essential in sourcing premium components that uphold product integrity, while tweezer factories like ours integrate these into streamlined production lines. This collaboration allows for efficient scaling, ensuring that tweezer exporter demands are met with consistent quality. For instance, our factory processes involve automated precision cutting and polishing, reducing defects and enhancing the non-slip grip for better handling during use.

Exploring Tweezer Exporters and Wholesalers

Tweezer exporters facilitate global distribution, connecting manufacturers like Olimor Beauty to international markets, while tweezer wholesalers handle bulk supplies for retailers. Additionally, tweezer OEM services enable customized production, tailoring designs to specific client needs without compromising on technical standards. This ecosystem supports innovation, such as our 96mm height and 10mm width models, which are engineered for portability and precision in everyday grooming tasks.